To all our customers, suppliers, and partners,

I hope that you, your family and friends are safe and well in these unprecedented times. I wanted to update you concerning the measures that Quorum Technologies has put in place to counter the impact of the pandemic on our business and how we are continuing to support users of Quorum equipment.

Quorum Technologies remained open for business throughout the pandemic, thanks to the flexibility and cooperation of our staff and the continued support of our customers and suppliers. Thank you for helping us to make it this far.

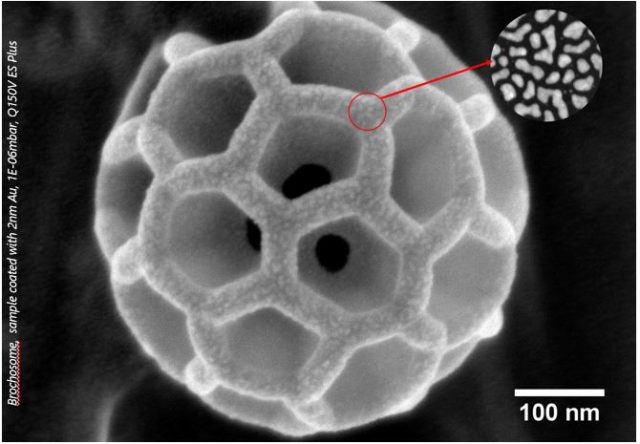

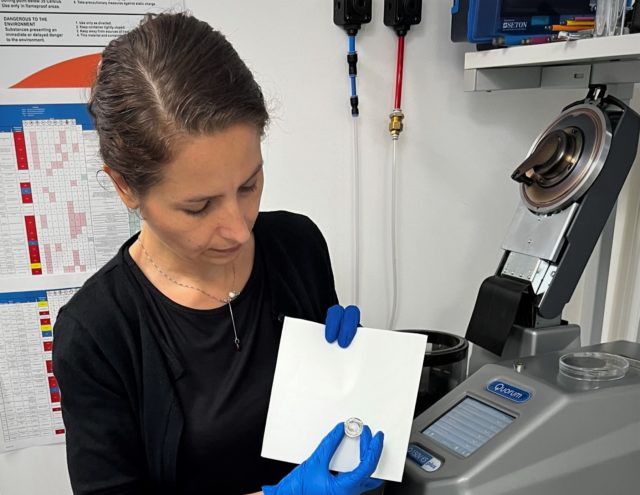

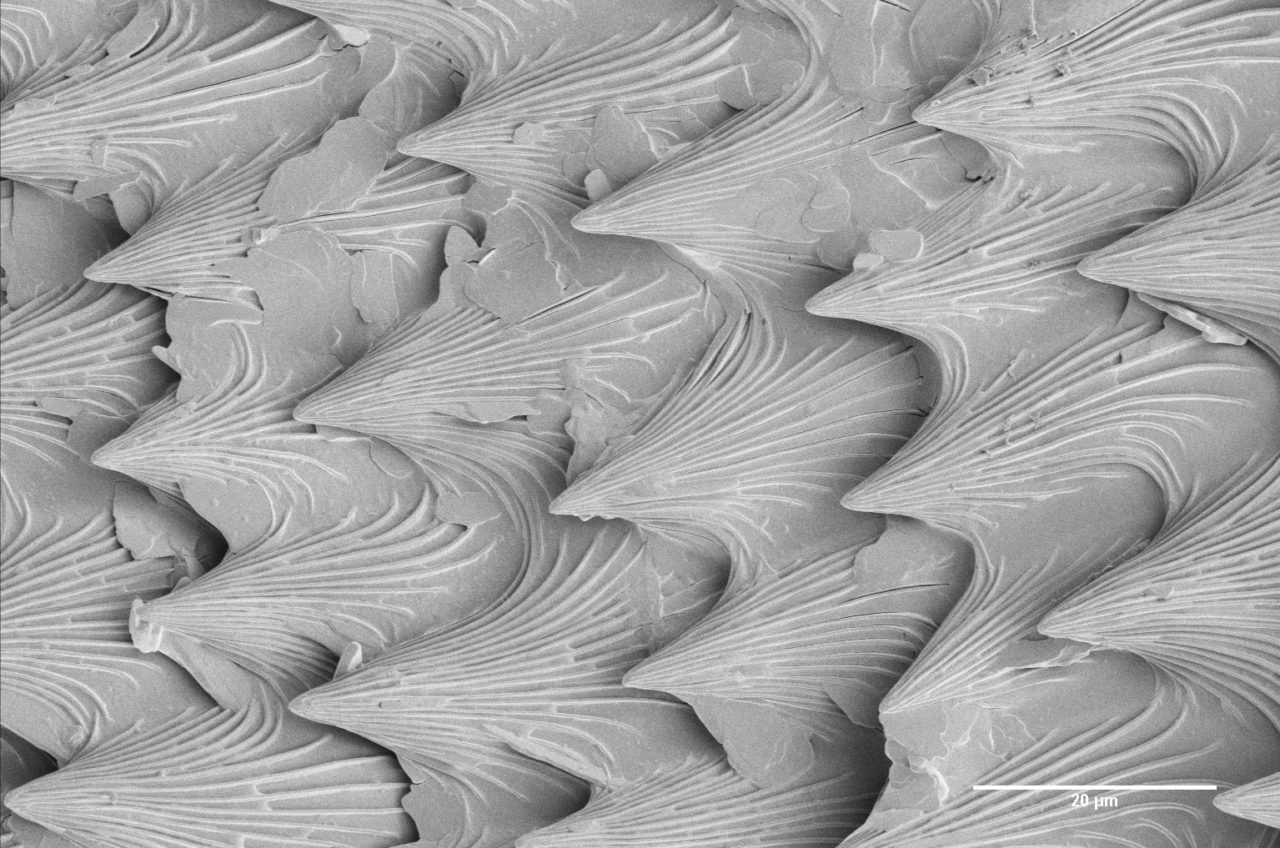

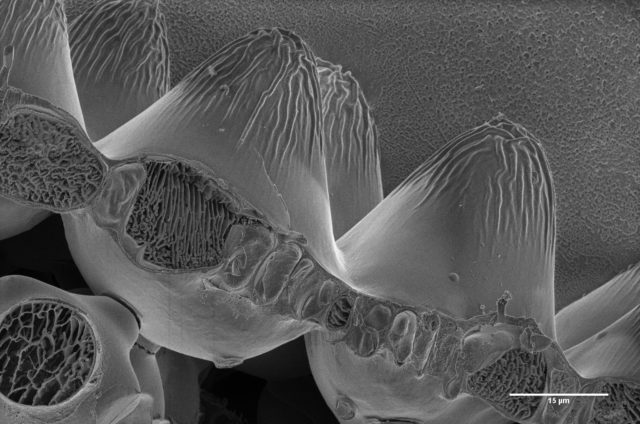

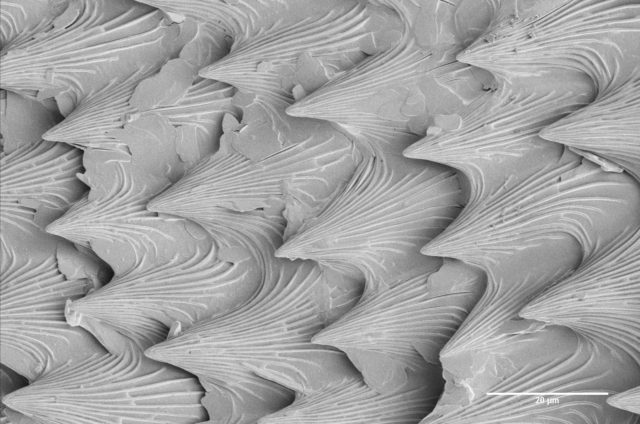

One of the reasons we felt it essential to keep operating was that our sample preparation equipment for Electron Microscopes was seen as a key technology for essential medical research. I am proud to say that, during the lockdown, we provided support and equipment to customers who are directly involved in research into the SARS-CoV-2 coronavirus and hopefully contributed in a small way towards eventually beating this virus.

Communication during the pandemic:

Our production sites in Laughton and Lewes were closed to external visitors at the start of lockdown. We have now opened again, with some restrictions:

- All visits are by appointment only.

- Instead of visiting the factory, your contact at Quorum may suggest off-site alternatives.

- If you do come to the factory, you will be required to comply with social-distancing measures, wear a face-mask, and follow strict guidelines on handwashing and sanitisation of work areas.

Many of our staff were directed to work from home, in keeping with the instructions issued by the U.K. government, or were furloughed during the lockdown. We have reorganised our offices and put in place additional measures to comply with guidelines for a CoViD-secure workplace and are now recalling staff to full-time work. Some back-office staff will continue to work from home but will be contactable as normal.

When contacting Quorum by phone, please use the main switchboard number, +44 (0) 1323 810981, and your call will be redirected to the appropriate number.

While we have been lucky in that no one at Quorum has yet contracted CoViD-19, the virus is still circulating in the U.K., and we may have unplanned absences due to illness or quarantine. For that reason, we cannot guarantee that individual staff members will always be available, and we continue to ask that you direct your calls and emails to teams, rather than to individuals, to enable a prompt response.

Our team emails are:

Accounts receivable/payable: [email protected]

Procurement: [email protected]

Product sales: [email protected]

Technical support: [email protected]

Supply of goods

Our Purchasing team has been working closely with our suppliers to ensure a continued supply of key parts, but there has been some disruption in supply chains which has impacted some of our older instruments. We are currently unable to guarantee lead-times for the following products:

K975X/K975S Turbo-Pumped Thermal Evaporators

K750X Peltier-Cooled EM Freeze Dryer

K775X Liquid Nitrogen Cooled Turbo-Pumped EM Freeze Dryer

K1050X RF Plasma Etcher/Asher/Cleaner

Customers with an urgent need to guarantee supply should contact the sales team as soon as possible to discuss. You can reach our sales team via the main switchboard number or by emailing them at [email protected].

Field service and installations

We have resumed field service activities, subject to complying with CoViD-secure guidelines. If you want to schedule a visit by our service engineers, you will be asked to provide information on the measures in place at your facility so we can conduct a risk assessment before scheduling a visit.

Unfortunately, our ability to travel overseas continues to be constrained by travel bans in certain countries and by the need to comply with quarantine requirements in others. We recognise that our equipment can be vital to research and we will travel where we can, but it may not be possible in every case. For example, if your country has a prohibition on visitors from the U.K. or requires an extended period of quarantine on arrival, we would be unable to schedule a field visit. Where travel is not possible, we will do our best to offer remote support by phone or email.

You can reach our service team via the main switchboard number or by emailing them at [email protected].

Thank you again for your support throughout this difficult period. We are, more than ever, grateful for that support and proud of the fact that you choose to work with us. I will update you again if we make further changes but please do not hesitate to contact me in the meantime if you have any concerns or questions.

Thank you for working with Quorum Technologies.

Yours sincerely,

Tony Larkin

Managing Director

Quorum Technologies Ltd