See a piece below from our customers at the Cambridge Advanced Imaging Centre at Cambridge University.

Cambridge Advanced Imaging Centre (CAIC) forms the hub of a network that draws together imaging activity across the whole University to serve the biomedical community. Many powerful modern imaging techniques have recently been developed, yet their exploitation in biology and biomedical research has largely been prevented by the high cost of their translation into widely available instruments and the specialist skills required for their use, including handling the vast volumes of data they generate. As a consequence, instruments developed in laboratories within specific Cambridge research programmes are often not available to the University’s wider biomedical research community.

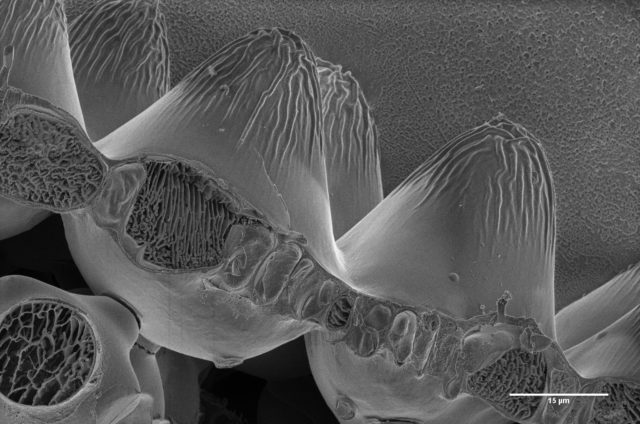

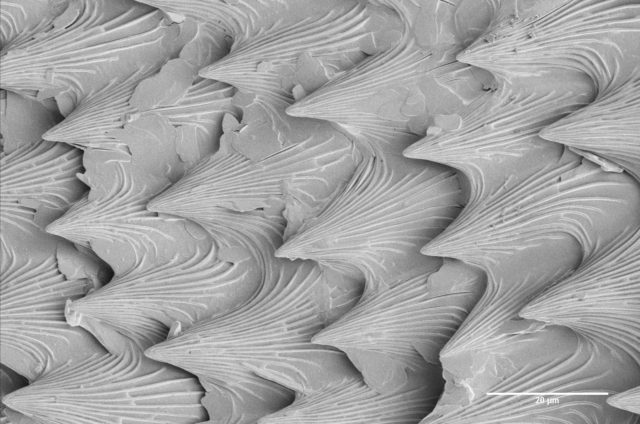

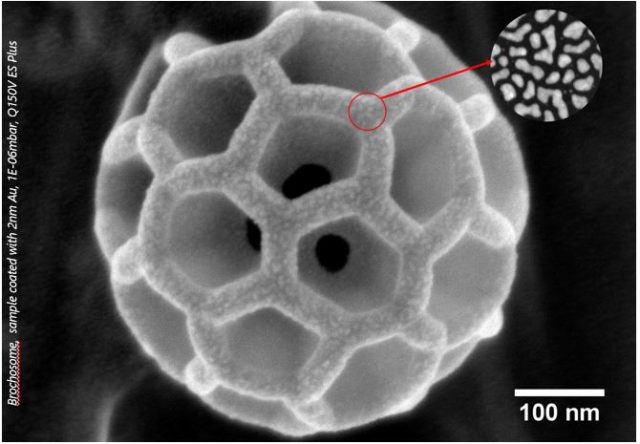

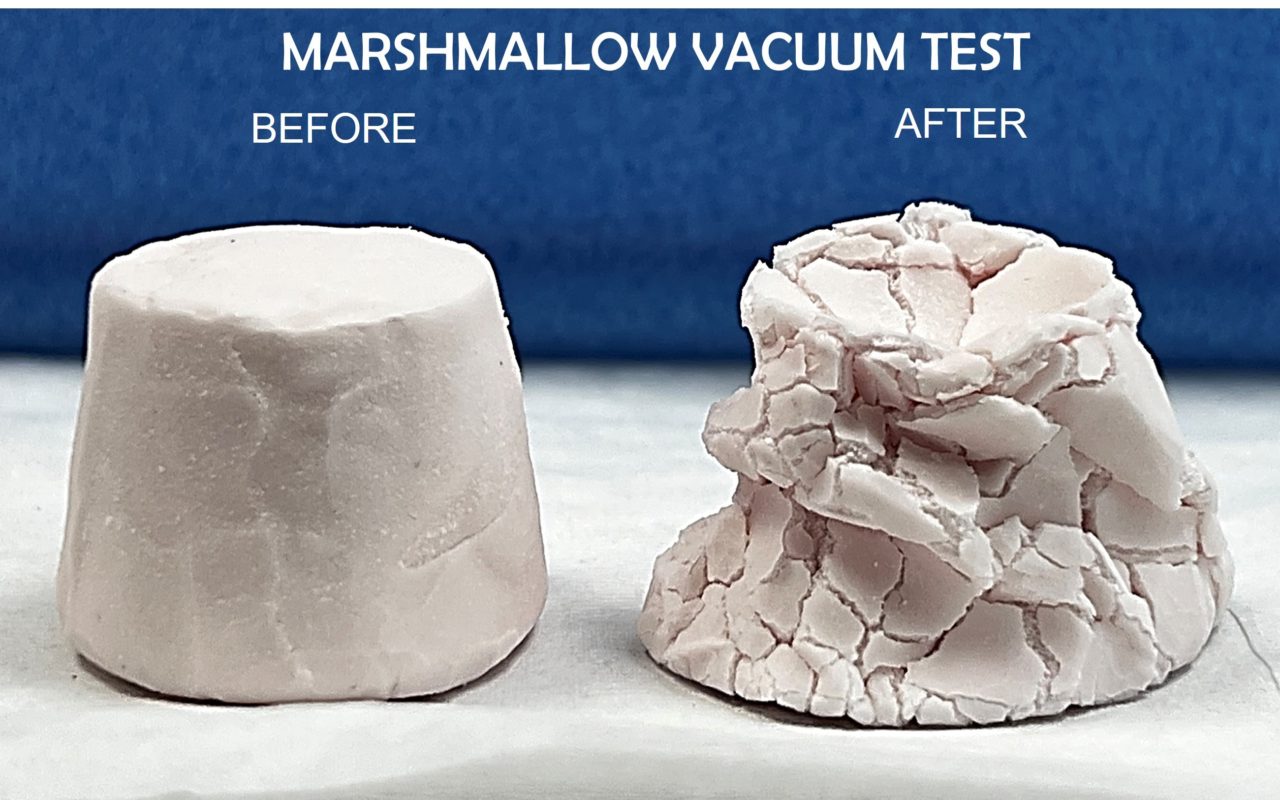

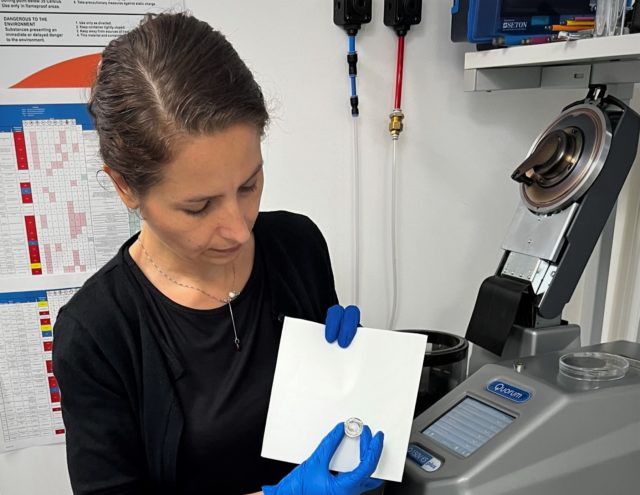

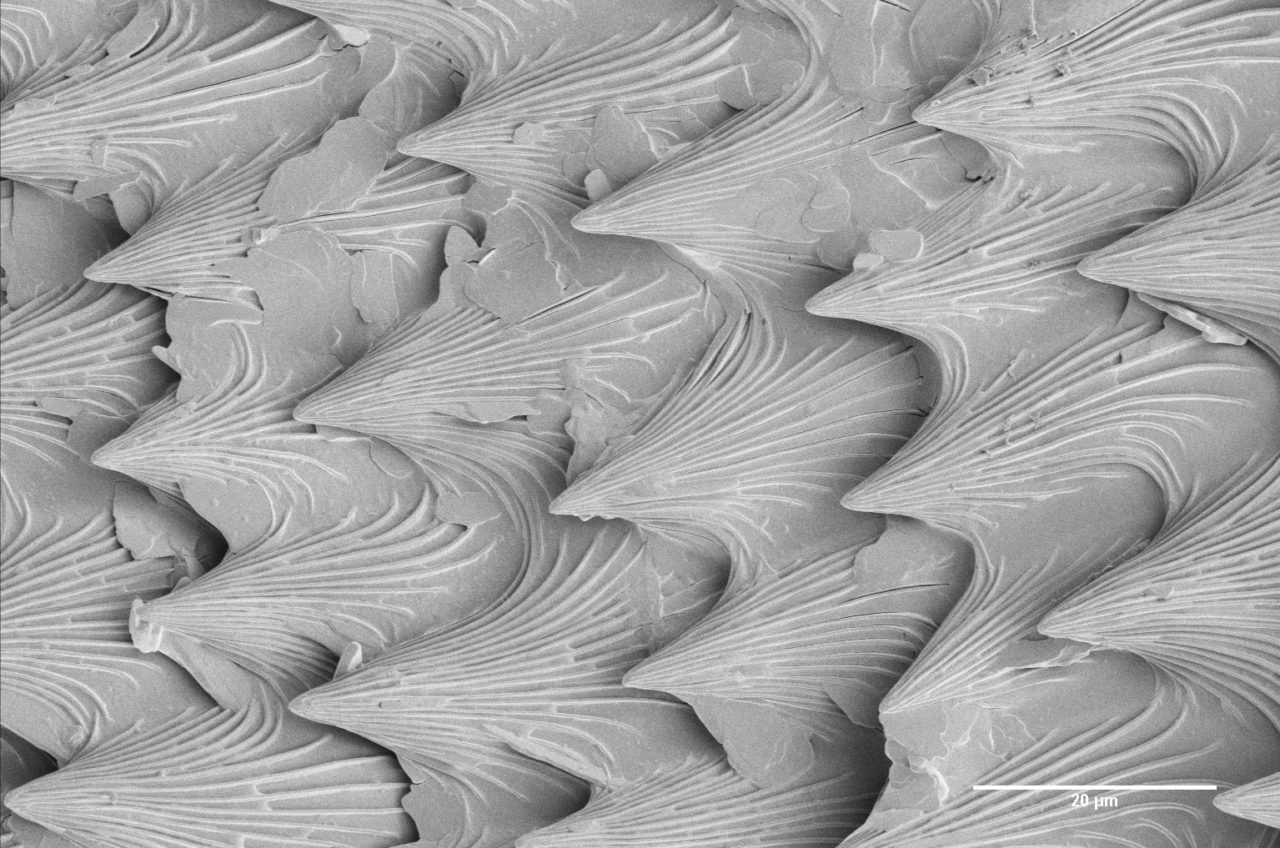

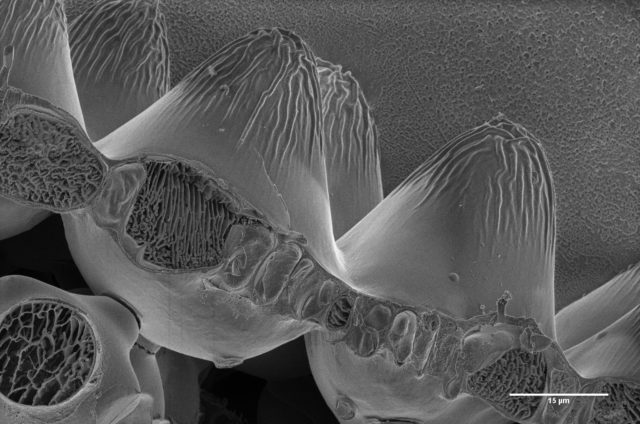

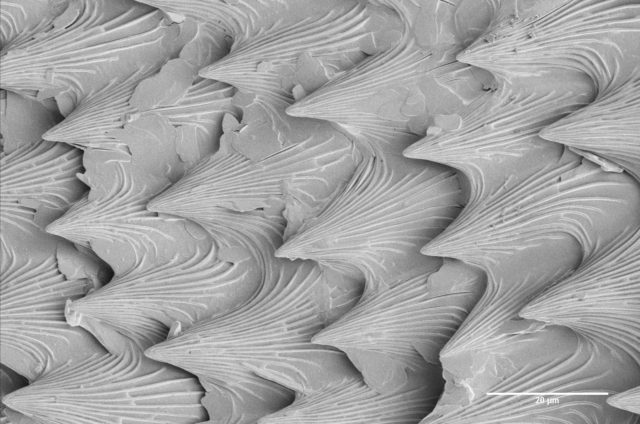

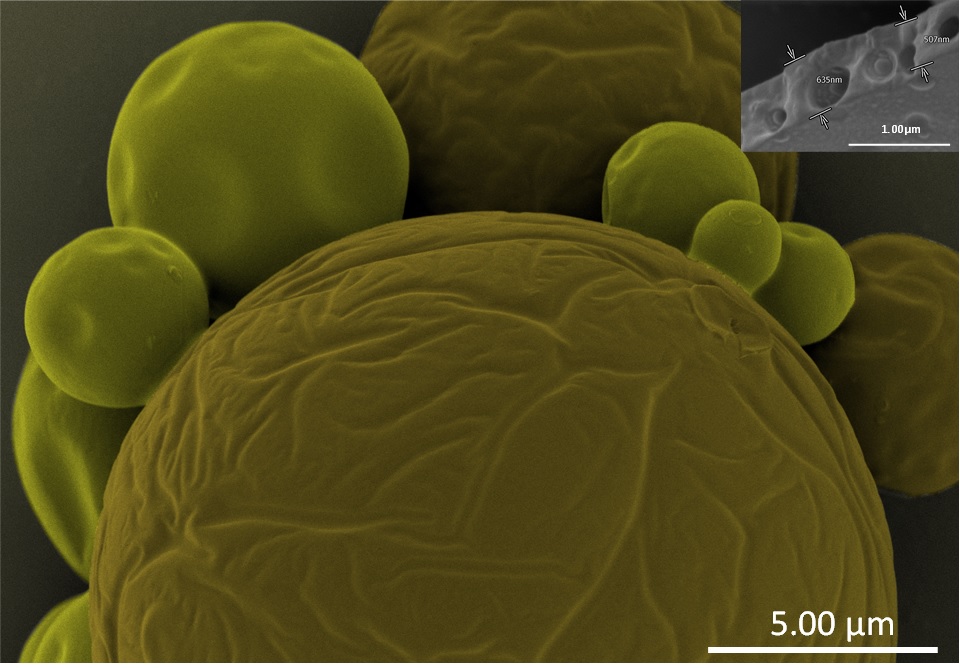

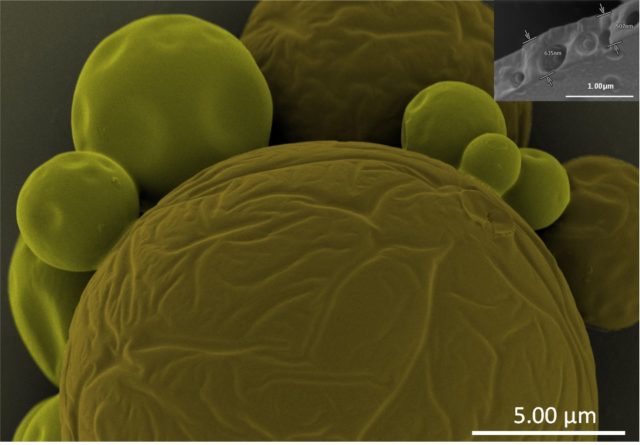

Our Verios 460 SEM is equipped with a Quorum PP3010T cryo-SEM preparation system. Cryo-SEM allows imaging of soft, hydrated biological or materials samples in a frozen state. One of the major advantages of cryo-SEM is that samples can be imaged with minimal preparation without the need of any prior fixation or dehydration steps; a disadvantage is that sample throughput is fairly low compared to other methods. Specimens are mounted on an appropriate cryo-SEM shuttle, are plunge-frozen in slushed liquid nitrogen and then transferred to a cooled prep stage. Once on the prep stage, samples can be fractured, sublimed to remove any residual ice, and coated to improve contrast and conductivity (CAIC routinely uses a platinum target). Then, the sample is transferred onto the SEM cryo-stage for imaging. As cryo-SEM requires about 2h of run-up and run-down time of the system apart from the actual imaging time, we recommend half-day or whole-day bookings.

Some images below from their cryo-SEM