Quorum Technologies remains open for business

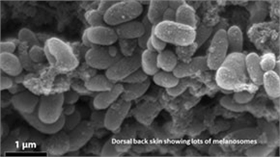

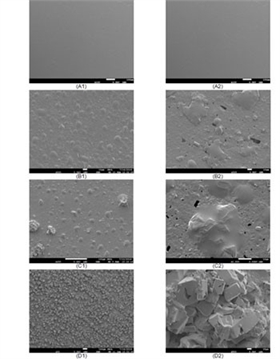

Quorum Technologies specialises in the manufacture of sample preparation equipment for Electron Microscopy, a key technology in medical research, and many of our customers are directly involved in research into the SARS-CoV-2 coronavirus. Therefore, it’s essential we stay in operation to support our customers in this vital work.

Our factory at Judges House remains open and production staff continue to work on-site to build and ship equipment. Staff are required to comply with social-distancing measures while at work and to follow strict guidelines on handwashing and sanitisation of work areas.

In keeping with the instructions issued by the U.K. government, all other staff have been directed to work from home, where possible.

Communication during the crisis

Judges House has been closed to external visitors until further notice. If you have an existing appointment to visit the factory, your counterpart at Quorum will contact you to arrange an alternative means of holding the meeting.

When contacting Quorum by phone, please use the main switchboard number, +44 (0) 1323 810981, and your call will be redirected to the appropriate number.

Due to an expected increase in absences due to illness, we cannot guarantee that individual staff members will be always available. Therefore, we ask that you direct your calls and emails to teams, rather than to individuals.

Our team emails are:

Supply of goods and services

Our Purchasing team has been working closely with our suppliers to ensure a continued supply of key parts and we are currently able to manufacture all products in our standard price list.

However, if global supply chains are disrupted, this may have an impact on our ability to supply certain products. Customers with an urgent need to guarantee supply should contact the sales team as soon as possible to discuss.

In some circumstances, it may be necessary to reserve certain products for customers engaged in essential research, in which case we ask for your understanding.

You can reach our sales team via the main switchboard number or by emailing them at [email protected].

Our ability to travel within the UK and overseas is constrained due to government requirements to limit “non-essential” travel. We recognise that our equipment can be vital to research and our team of service engineers stands ready to travel where possible, for example, to help with requests for essential service at medical institutions researching the coronavirus. Where travel is not allowed, we will do our best to offer remote support by phone or email.

You can reach our service team via the main switchboard number or by emailing them at [email protected].

These are extraordinary times. More than ever, we at Quorum are committed to doing what we can to support the work of all the scientists and researchers who use and rely on our equipment. We will keep you updated on further changes but please do not hesitate to contact us in the meantime if you have any concerns or questions.

Thank you for working with Quorum Technologies.

Yours sincerely,

Tony Larkin

Managing Director

Quorum Technologies Ltd.

Reference

Reference